Propellant batches were made in 20 gram sizes. Untested formulas should never be made in large batches. Should an unexpected reaction or ignition occur small size is an added safety factor. But don't be fooled into complacency. For example: 20 grams of f1ash powder can maim or ki11 a person.

OK: safety rant off.

Materials:

The Potassium nitrate (KNO3) was fine powder (Stock #C170 - OX) from Firefox

The Sorbitol was Sorbo-Gem food grade powder. This grade of sorbitol is available from PVC ONLY

The Graphite and Carbospheres are from Firefox

The Willow charcoal was made from willow branches and anaerobic heating.

The melting pot is a small triple batch double boiler utilizing paraffin as the heat transfer agent.

Process:

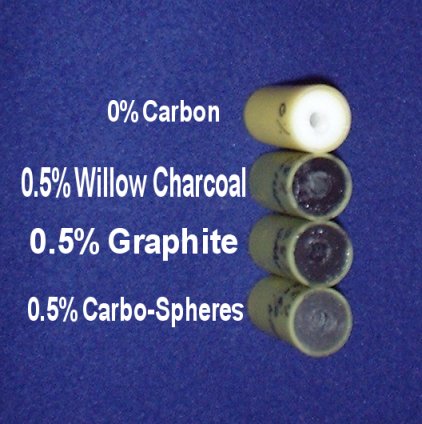

Eighty grams of standard 65/35 KN/Sorbitol was prepared in powder form. From this batch four aliquots of 20 grams each were split out. To one aliquot no carbon was added. To the next 0.1gms dry airfloat Willow charcoal powder was added. To the next 0.1 gram fine graphite and to the last aliquot 0.1 grams Carbospheres was added.

The resulting carbon percentages are 0.5% each

The formulas were melted and poured into Bates grains. These are slightly progressive grains due to the length. (34mm length, 17mm width, 5 mm core, one end exposed, and the other end inhibited.)

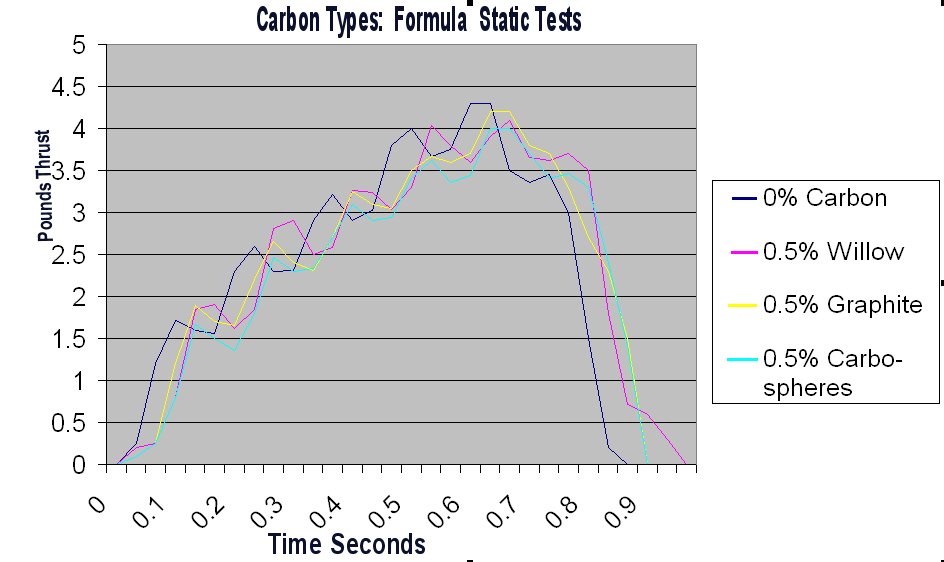

The grains are placed into motor casings, with 4.5mm nozzle, and static tested with a thrust curve generated.

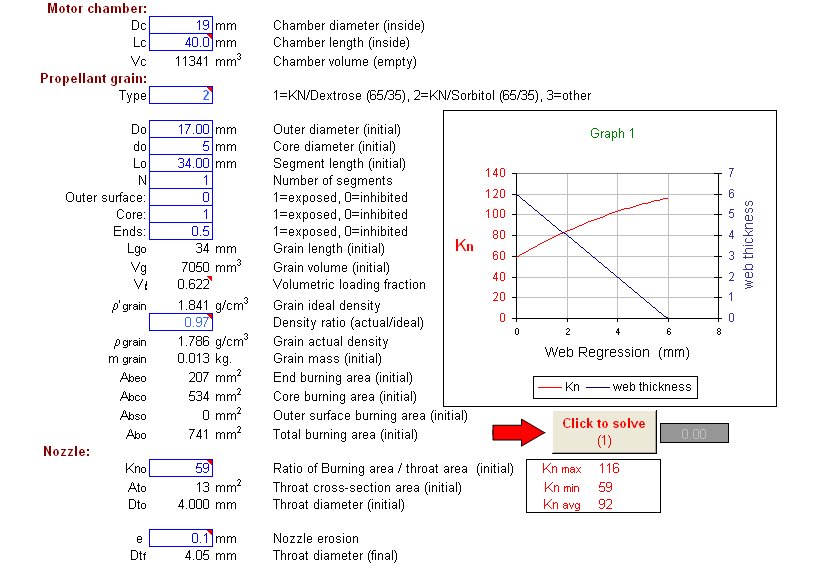

To calculate density of the control formula as well as the motor KN values the grain dimensions were plugged into SRM.xls

The grain and chamber dimensions are input. The actual grain weighed 13.2 grams so I adjusted the density ratio (actual/ideal) till the mass came to 13 grams. The density ratio was 0.97 Nice!

The static tests showed a small amount of erosion from 4.0mm nozzle opening to between 4.0 and 4.1 (I called it 4.05)

This data entered can be seen in the image above with the KN of the motor throughout the burn. These motors are somewhat progressive.

Minimum and starting KN = 59

Average KN = 92

Maximum KN = 116