Propellant batches were made in 20 gram sizes. Untested formulas should never be made in large batches. Should an unexpected reaction or ignition occur small size is an added safety factor.

Materials:

The Potassium nitrate (KNO3) was fine powder (Stock #C170 - OX) from Firefox

The Sorbitol was Sorbo-Gem food grade powder. This grade of sorbitol is available from PVC ONLY

The Titanium powder is -325 mesh sponge from Firefox (Stock #C198)

The melting pot is a small triple batch double boiler utilizing paraffin as the heat transfer agent.

Process:

The Ti sponge is extremely fine. It is shipped wet for safety reasons. An Email to Firefox confirmed that it is best to keep it stored wet. This prevents an air float suspension that is a health hazard and an explosion hazard. Each formula batch was weighed seperately and mixed well

The resulting formulas had weight ratios for KNO3/Sorbitol/Ti of:

65/35

65/33/2

65/30/5

65/25/10

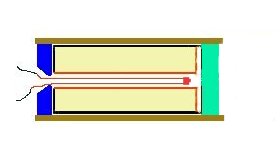

The formulas were melted and poured into Bates grains. These are slightly progressive grains due to the length. (34mm length, 17mm width, 5 mm core, one end exposed, and the other end inhibited.)

The grains are placed into motor casings, with 4.5mm nozzle, and static tested with a thrust curve generated.

The thrust curve is measured in pounds so it is converted to newtons and entered into Excel. From there Average Thrust, and Total Impulse values are calculated.