Materials:

The Potassium nitrate (KNO3) was fine powder (Stock #C170 - OX) from Firefox

The Sorbitol was Sorbo-Gem food grade powder. This grade of sorbitol is available from PVC ONLY

The Dextrose was anhydrous dextrose reagent grade

The melting pot is a small triple batch double boiler utilizing paraffin as the heat transfer agent.

Process:

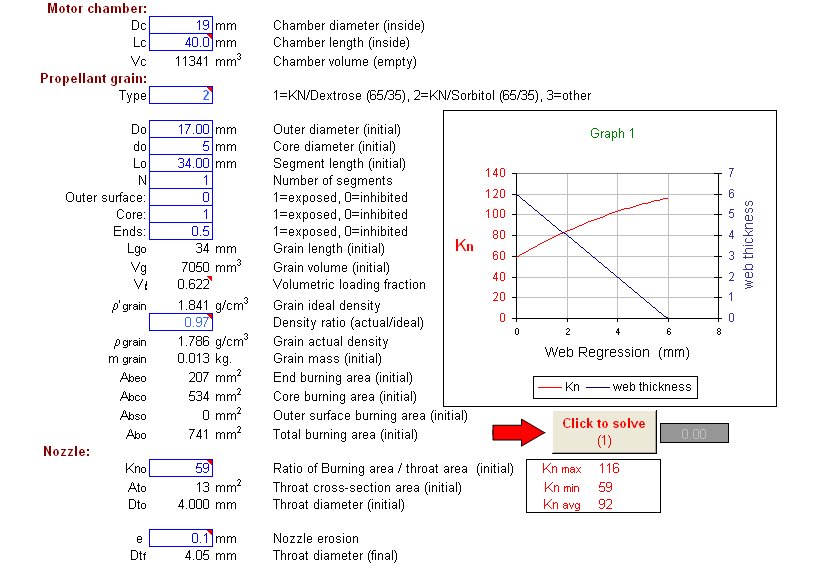

The formulas were melted and poured into Bates grains. These are slightly progressive grains due to the length. (34mm length, 17mm width, 5 mm core, one end exposed, and the other end inhibited.)

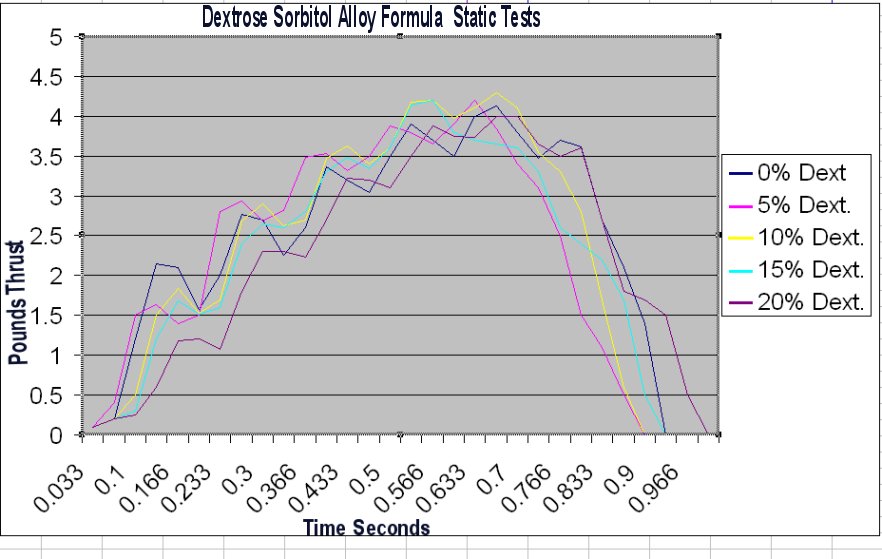

The grains are placed into motor casings, with 4.0mm nozzle, and static tested with a thrust curve generated.

To calculate density of the control formula as well as the motor KN values the grain dimensions were plugged into SRM.xls

The grain and chamber dimensions are input. The control grain weighed 13.2 grams so I adjusted the density ratio (actual/ideal) till the mass came to 13 grams. The density ratio for the control grain was 0.97 Nice!

The static tests showed a small amount of erosion from 4.0mm nozzle opening to between 4.0 and 4.1 (I called it 4.05)

This data entered can be seen in the image above with the KN of the motor throughout the burn. These motors are somewhat progressive.

Minimum and starting KN = 59

Average KN = 92

Maximum KN = 116