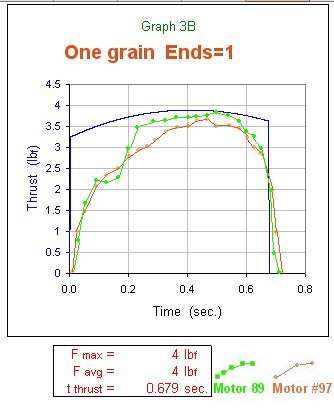

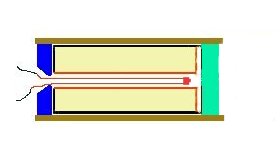

The graph above has the sim with ends=1 so SRM calculates both ends burning. This gives an expected fairly neutral burn. The two statics though are somewhat progressive. Not surprising since one end is inhibited. (See motor image above, red areas represent unhibited surfaces at ignition.

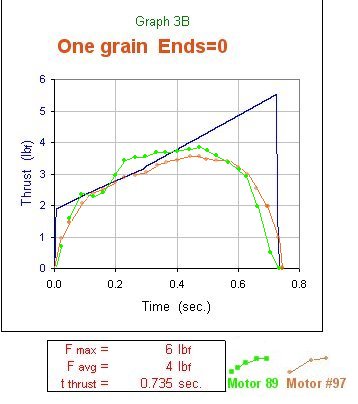

Above is the sim with ends=0 meaning that both ends are calculated as inhibited.

Like the "two" (1.5) grain motor (my standard D16 motor) the second half of the static burn is not as progressive as the sim.

Again this makes sense since the static motors have one end per grain exposed.

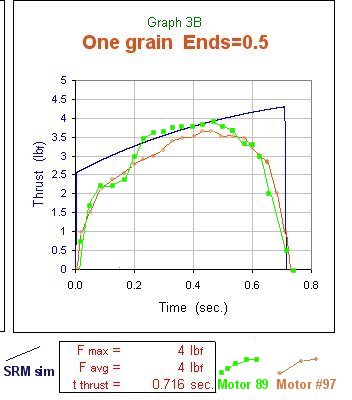

So once again to compensate in the sim input we enter ends=0.5

This will calculate that one end burns and the other is inhibited.

Now.. does the adjusted sim reflect reality?

See graph image below:

Hit Reload if you don't see motor image

Hit Reload if you don't see motor image